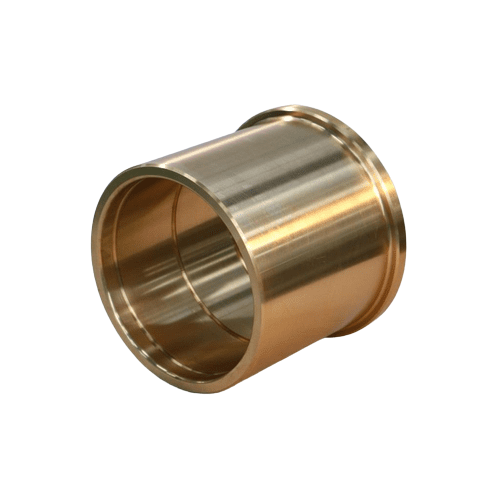

Product Name: Engine Bushes

Sizes, Applications, Alloys, Specifications, and FAQs

Introduction: Engine bushes are integral components in the automotive and machinery industry, providing crucial support, vibration damping, and wear resistance. Whether you’re a vehicle enthusiast, manufacturer, or simply curious about these essential components, this comprehensive guide will furnish you with all the information you need. In this article, we will delve into the manufacturing process, applications, engine bush alloys, specifications, technical data, and frequently asked questions about engine bushes.

Manufacturing Process: Engine bushes are typically manufactured using processes like machining or forging, which result in durable and precise components capable of withstanding the rigors of engine operation.

Sizes: Engine bushes come in various sizes to fit a wide range of engine types and machinery. Common size ranges include inner diameters from 1/4 inch to 4 inches or more, outer diameters from 1/2 inch to 6 inches, and lengths from 1 inch to 6 inches or more. These sizes are designed to accommodate different engine configurations and requirements.

Applications: Engine bushes are used in numerous applications to provide stability and reliability. Some common applications include:

- Automotive Engines: Engine bushes play a crucial role in automotive engines, supporting crankshafts, camshafts, and other critical components.

- Industrial Machinery: They are used in industrial machinery such as generators, pumps, and compressors to reduce vibration and ensure smooth operation.

- Aerospace Industry: Engine bushes are employed in aircraft engines, contributing to their reliability and safety.

- Marine Engines: Used in marine engines to withstand the harsh conditions of saltwater and provide stability.

- Power Generation: Engine bushes are essential in power plant equipment to support generators and other machinery.

Alloys: Engine bushes are typically made from high-strength materials, such as alloy steel, bronze, or synthetic materials. The choice of alloy depends on factors like load-bearing capacity, wear resistance, and the specific application.

Specifications: Engine bushes must meet industry standards and specifications to ensure their performance and durability in engine applications. These standards may vary depending on the type of bush and its intended use.

Technical Data Sheet: For in-depth technical information, consult the manufacturer’s technical data sheet for the specific engine bush alloy and type you intend to use. These sheets provide insights into mechanical properties, chemical composition, and more.

FAQs:

Q1. How often should engine bushes be replaced in a vehicle or machinery? A1. The replacement frequency of engine bushes depends on factors like usage, load, and maintenance practices. Regular inspections and proper lubrication can help extend their lifespan.

Q2. Can I replace engine bushes myself, or should I seek professional help? A2. Replacing engine bushes often requires technical expertise and access to proper tools. It is recommended to have a trained technician or engineer perform the replacement to ensure safety and proper functionality.

Q3. What are the signs of worn-out engine bushes? A3. Signs of worn-out engine bushes include increased vibration, noise during operation, reduced stability, and changes in engine performance.

Q4. How do I choose the right engine bush for a specific application? A4. The choice of engine bush depends on factors such as engine type, load-bearing requirements, and operating conditions. Consulting with a materials engineer or the manufacturer can help you select the best bush for your specific needs.

In conclusion, engine bushes are indispensable components that provide crucial support and reliability in various industries, including automotive, industrial machinery, aerospace, and more. Whether you’re a manufacturer, engineer, or someone intrigued by these critical components, this guide equips you with the information needed to make informed decisions about their selection and use.